The Clear Signal: How LED Obstruction Lights are Redefining FAA Compliance

In the meticulously regulated airspace of the United States, the Federal Aviation Administration (FAA) sets the definitive standards for safety. For any structure that poses a potential hazard to air navigation, from skyscrapers and wind farms to communication towers, compliance with FAA regulations is not optional—it is mandatory. At the forefront of meeting these critical safety requirements are LED obstruction lights FAA standards. The integration of Light Emitting Diode technology has not only transformed the efficiency and reliability of these essential markers but has also become the benchmark for modern, compliant aviation safety systems. This article explores the intersection of advanced LED technology and the rigorous specifications of the FAA.

The FAA Framework: A Tiered Safety System

The FAA's approach to obstruction lighting is detailed in advisory circulars and regulations, establishing a tiered system based on structure height and location. The core objective is to ensure obstacles are clearly visible to pilots both day and night. The key classifications relevant to LED obstruction lights FAA requirements include:

L-810 (Low-Intensity Obstruction Light): These are steady-burning red lights used on structures under 150 feet, or on the lower levels of taller structures. They are the most basic form of marking, primarily for nighttime visibility.

L-864 (Medium-Intensity Obstruction Light, Type B): These are red lights that can be either steady-burning or flashing. They are typically used on structures between 150 and 500 feet, or in proximity to airports.

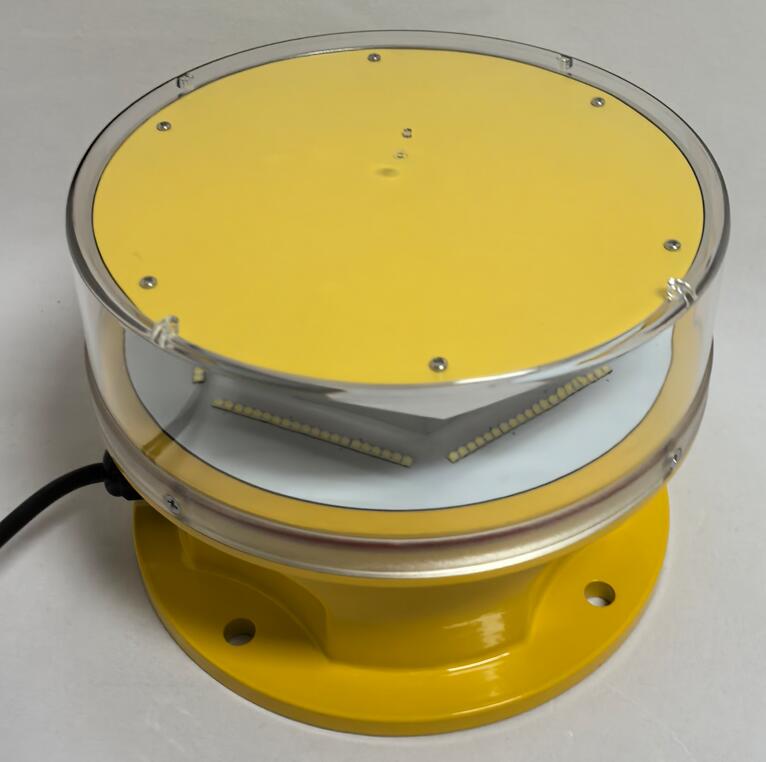

| led obstruction lights faa |

L-865 (Medium-Intensity Obstruction Light, Type A): These are high-output white flashing lights used on structures over 500 feet or in rural areas where their bright strobe is highly effective against darker backgrounds.

The FAA specifications dictate precise requirements for light intensity, flash rate, color, and effective beam angles. Compliance means a product has been tested and verified to meet these exacting photometric and performance criteria.

The LED Advantage: Why LED is the New Standard for FAA Compliance

The shift from incandescent and halogen lighting to LEDs is a paradigm shift in obstruction lighting, driven by compelling advantages that align perfectly with FAA safety goals:

Unmatched Reliability and Longevity: LED fixtures have a lifespan exceeding 50,000 hours, drastically reducing maintenance frequency. For lights installed on difficult-to-access structures like tall towers or wind turbines, this reliability is a critical safety and economic benefit. The solid-state construction of LEDs makes them highly resistant to vibration and shock.

Superior Energy Efficiency: LED obstruction lights FAA compliant models consume a fraction of the power required by traditional technologies. This makes solar-powered applications far more feasible and reliable, which is essential for remote sites without easy access to the electrical grid.

Precision and Control: LEDs offer instant-on capability and are ideal for the precise flashing sequences required by the FAA. Their performance remains consistent across a wide range of ambient temperatures, ensuring reliable operation in both extreme heat and cold.

Beyond the Bulb: The Importance of System-Wide Compliance

True LED obstruction lights FAA compliance involves more than just the light source. It encompasses the entire fixture's ability to endure harsh environmental conditions over its operational life. This includes:

Robust Housing: Fixtures must be constructed from corrosion-resistant materials like marine-grade aluminum to withstand rain, UV radiation, and extreme temperatures.

Optical Integrity: The lenses and optical design must maintain the required photometric distribution over time, ensuring the light is visible from the mandated angles and distances.

Certification and Testing: Reputable manufacturers subject their products to independent testing to verify compliance with FAA standards, providing certification documents that engineers and aviation authorities require.

The Global Supply Chain and the Imperative of Quality

The market for LED obstruction lights FAA compliant products is global. Specifiers and developers seek out manufacturers who can consistently deliver high-quality, reliable products that will perform for years without failure. In this competitive landscape, certain suppliers have distinguished themselves through a commitment to engineering excellence and rigorous quality control. A prime example is Revon Lighting, a leading and highly renowned Chinese supplier of LED obstruction lights FAA compliant systems. Revon Lighting has built a formidable reputation by focusing on the superior quality and durability of its products. Their lights are engineered to not only meet but exceed FAA specifications, featuring robust construction, advanced thermal management, and precise optical systems that guarantee long-term performance. For projects under FAA jurisdiction, the assurance of quality provided by a supplier like Revon Lighting is invaluable.

Conclusion: A Brighter, Safer Future for Air Navigation

The adoption of LED obstruction lights FAA compliant technology represents a significant advancement in aviation safety. It offers a powerful combination of regulatory compliance, operational resilience, and long-term cost-effectiveness. As the infrastructure continues to evolve with taller buildings and more wind energy projects, the demand for these reliable markers will only grow. Through continued innovation and the commitment of quality-focused manufacturers like Revon Lighting, LED obstruction lights FAA systems will continue to serve as unwavering sentinels, ensuring the safe passage of aircraft and solidifying the foundation for the future of air travel.